MI cable is generally the preferred choice in the manufacturing of temperature sensors due to its durability and superior thermal conductivity. However, the cutting and straightening of MI cables for this production process is a highly skilled, labor-intensive and time-consuming task.

The outer sheath, combined with the MgO insulation, requires a specific cutting technique to ensure a burr-free product. Furthermore, to effectively grind through compact MgO, specialized cutting tools and techniques are required to prevent wear on the blades. These technical issues not only lead to higher labor costs but also increase the risk of human error, which can compromise the quality of the final product.

Our CS-1100 cutting and straightening machine for MI cables solves these challenges by automating the process.

+ High precision cutting and straightening of MI cables

+ Handles a wide range of cable lengths and diameters (1-8mm)

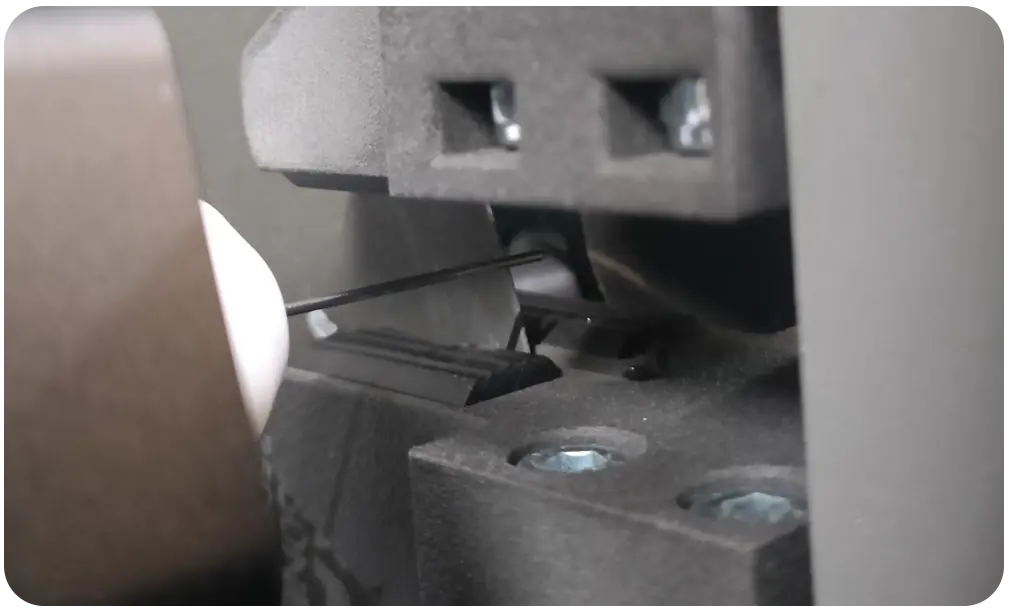

+ Pneumatic clamping system and custom blades provides burr free cutting

+ Software gives timely notifications when internal parts require replacement

+ Advanced safety features to protect operators and prevent accidents

+ Malfunction alerts are highly visible (flashing lights) and easily localized (on-screen specifications)

+ Extremely tight tolerances on cut lengths

The CS-1100 is equipped with a LCD screen providing clear and detailed information on the status of the machine, including measurements, cutting length, and cutting speed. The interface is user-friendly, designed to make the CS-1100 easy to operate and monitor during use

Our cutting and straightening machine for MI cables is equipped with an exceptional feature – a movement encoder. This ensures that each cut is made at the precise point where it is needed, resulting in consistent and accurate cuts every time.

The feeding system is a standout feature, designed for precision and reliability. A constant pressure is applied to the MI cable, resulting in a secure grip that ensures the cable moves smoothly through the machine.

Its remarkably thin profile is a key feature, allowing for precision cuts without compromising the integrity of the MI cable or the precision of the cut. The cutting disc advanced design minimizes heat generation, extending the lifetime of the disc.

Our pneumatic clamping mechanism delivers a firm, precise hold for clean cable cuts down to 20 mm. A built-in slide, powered by the Venturi effect, smoothly directs cut parts into a basket. This system eliminates jams with small diameters and ensures faster, more reliable operation.

The smart and user-friendly software in our CS-1100 machine is designed with a range of features that help to improve efficiency and reduce downtime.

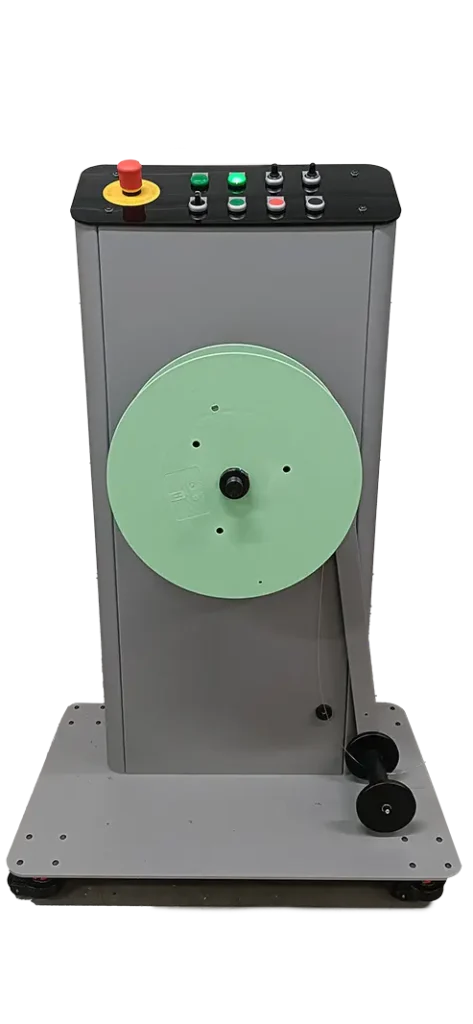

To handle smaller OD MI cables, we have developed an automatic spool holder that can be placed next to the CS-1100. This spool holder is specifically designed for processing MI cables with smaller diameters.

The spool holder uses a tensioner arm that pivots outward to maintain the correct cable tension. This arm is equipped with a position sensor, enabling seamless integration with the machine’s software. When the tensioner arm is raised, the CS-1100 automatically starts feeding, which prevents small-diameter MI cables from becoming tangled.

We strongly recommend using this solution when working with smaller diameter cables.

The CS-1100 and spool holder can either be purchased outright or obtained through a lease construction. The lease option includes an extensive service contract for the entire lease period. The lease arrangement can be linked to the amount of MI cable you purchase from Kamet, meaning that higher purchase volumes may result in more favorable conditions. If you are interested, we can provide a calculation tailored to your yearly MI cable consumption.

Leasing may also offer fiscal benefits, as lease payments are typically considered business expenses and can reduce the taxable profit of your company. This can make leasing an attractive alternative to an upfront investment.

Our mission is to revolutionize the world of industrial automation by producing machines that enable customers to automate the manufacture of industrial temperature sensors.

Let’s chat to see if we can help you with your production process.